Jadnashua

Retired Defense Industry Engineer xxx

Fluid dynamics is a complex science, but the fluid does tend to stick to the sides of the pipe.

I'll accept the measured performance of the engineers who design & test stuff above anybody's armchair theory. I accept Terry's (and other's) less rigorous field test measurements too.

I fully accept that not everyone is comfortable with having a potable wrap in contact with the drain, but I also accept that as-built these do not constitute a code violation in most places. The double walled character and the tightness of the wrap (=no mechanical vibe & wear) are probably the differentiating factor that gives the assembly a pass, where potable piping field-assembled in contact with drains would be a violation. Without the minutes of the presiding/deciding body to refer to we can only speculate. But from one vendors' website:

http://ecoinnovation.ca/thermodrainpurchase/

Natural Resources Canada maintains a third-party tested performance list here.

http://www.gfxtechnology.com/

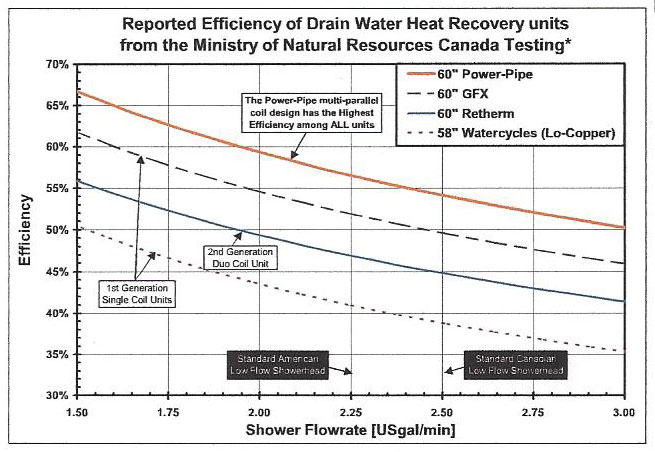

The Canadians tried and failed to measure the heat recovery of room-temp and tepid water drains using these things, but failed. The delta-Ts are too small, and even using the theoretical model the result would be smaller than the measurement error for unbalance high drain-gpm not exactly simultaneous slow-potable flows like toilet flushes. (Heat exchange efficiency falls with higher flow rates & unbalanced flow.)

| |

Here is a digital thermometer that you could use to test your flow.... just be sure to clean it off before sticking it in the Thanks Giving turkey

That looks painful not digital.

lol

I honestly would not waste the time to do it...

you have to remember that your room temp wil lbe higher

than the temps inside the pipe......so its basically a total circle ....

I would be interested in seeing what one would do on the flu pipe...

go ahead and wrap the chimmney with aluminum foil to protect the copper

from the flu pipe if you must..... that would be a better experiment because of the

higher heats....

Knock yerself out, take good measurements, but the exhaust gas heat extraction road is a well-trodden path in the industrial boiler applications, and they're neither simple nor cheap. (Were they simple and scalable it would have long since found it's way in to domestic hot water applications.)

This is awkward, but...

It looks like you're using an ad blocker. We get it, but (1) terrylove.com can't live without ads, and (2) ad blockers can cause issues with videos and comments. If you'd like to support the site, please allow ads.

If any particular ad is your REASON for blocking ads, please let us know. We might be able to do something about it. Thanks.