CHOLLA BOB

New Member

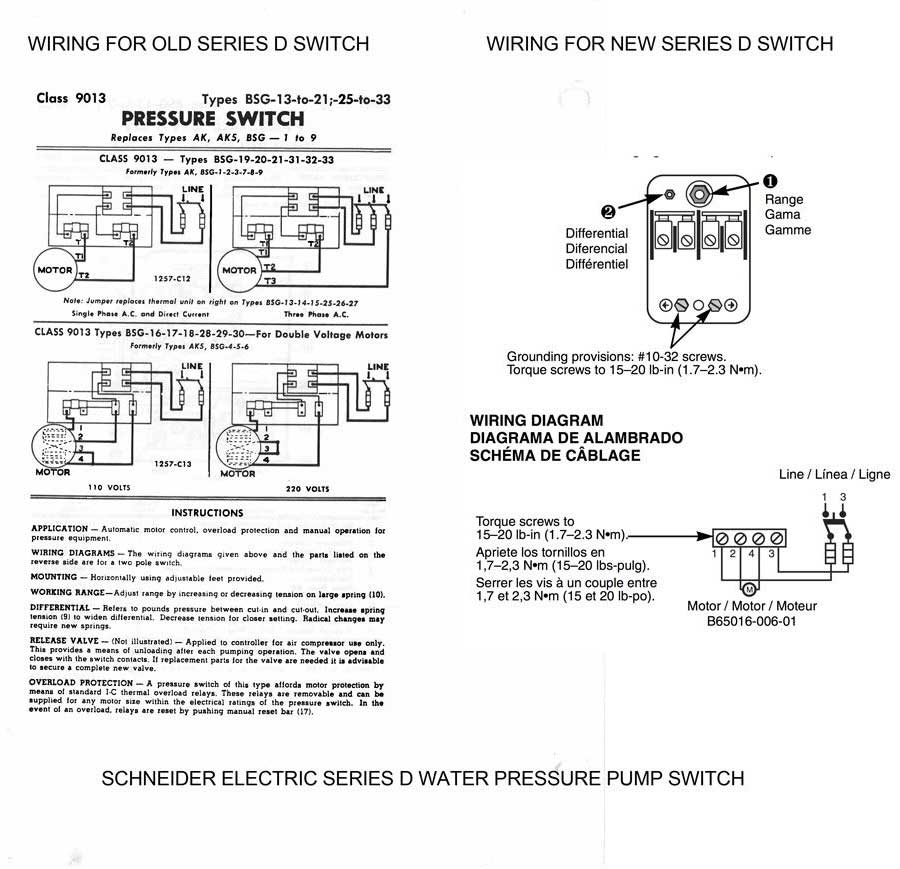

I did a water run today and priced the Schedule 40. No local wire except 4 wire grey UF (H H N G) priced at 110.00 for 80 feet. Planning to find separate strand wiring 10g TW rated wiring. I will run the four strand to the well pump pressure switch, and wire ahead the sub-panel and 120V outlet latter as the water is the priority now. Is Schedule 40 1 inch a better way to go for running wire and durability than 3/4 inch? The hardware store said it may be overkill. I will look into the ground rod for the well house.

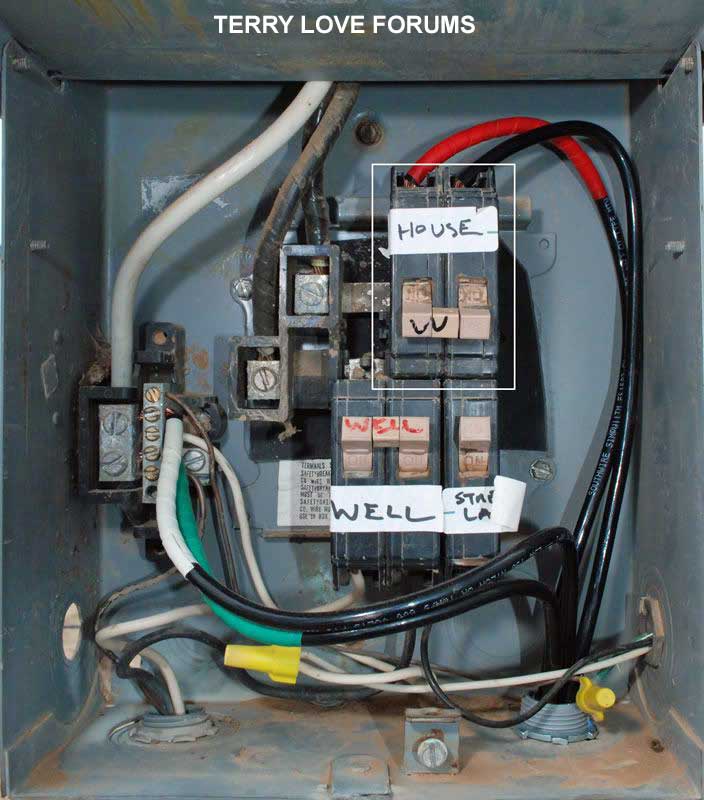

The future sub-panel will have separate ground and neutral bars; main panel is the only place they are bonded. Trailer does not have a grounding rod; only main panel. The utility meter is grounded by wire to earth driven rod. The main service pole breaker box is grounded through galvanized steel pipe (no ground wire) to the utility meter box. The electrician said this should be upgraded as it is no longer to code. Some states still allow this, but I was surprised when I saw this working on the main box this summer.

Replied this morning but it never showed up in the forum, if this is out there already. Stocking up on the chicken broth and looking forward to the mud trenches tomorrow.

The future sub-panel will have separate ground and neutral bars; main panel is the only place they are bonded. Trailer does not have a grounding rod; only main panel. The utility meter is grounded by wire to earth driven rod. The main service pole breaker box is grounded through galvanized steel pipe (no ground wire) to the utility meter box. The electrician said this should be upgraded as it is no longer to code. Some states still allow this, but I was surprised when I saw this working on the main box this summer.

Replied this morning but it never showed up in the forum, if this is out there already. Stocking up on the chicken broth and looking forward to the mud trenches tomorrow.

Last edited: