JCH

Member

There are many heating mats that can be used for sure but I'm more of a fan of heating cables.

It took me a long time to get the rest of the room ready, but I finally installed NuHeat heating cables this week and passed my electrical inspection. Really nice system to work with.

Then this weekend I rolled on Mapei Primer T onto the exterior-grade plywood subfloor (goes on pink, but dries clear -- very cool); stapled down Mapelath plastic lath; then poured 1/2" of Mapei Novoplan Easy SLC.

Thank you all for your recommendations so far--beautiful results. Floor is now true and level -- less than 1mm (1/25") gap when checking with a 4 foot level.

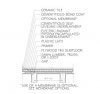

Which brings me to the question about the next step... the decoupling/anti-fracture layer (as specified by the TCNA's handbook):

Once the cable heat is installed you might consider a product like Schluter's 'Ditra', Nobel Company's 'Nobel TS' or Mapei's 'Crack and Sound Membrane' over your levelling pour. Remember if you use the Ditra product you will strictly reduce the amount of setting materials available to you. Here in Vancouver the crews I'm working with have been using lots of the Mapei product and many of the setters online have been using Nobel TS. Mostly because they can use the same thin-set to set above and below the membrane.

I've been so pleased with the Mapei products I've used so far (Primer T, Mapelath, and Novoplan Easy) that I'd like to try staying with them for the decoupling layer. Called their Tech Services hotline but they said they don't sell anything similar to Schluter's Ditra.

Looked on Mapei's website for 'Crack and Sound Membrane' but found quite a few products that have that in their description:

- Mapeguard 2 sheet membrane,

- Mapelastic 315,

- Mapelastic AquaDefense,

- Mapelastic CL, and

- Mapelastic HPG.

**Are any of these the product you're suggesting??

If this is your first bathroom renovation you might further consider using a liquid membrane for all these steps including the bathtubs walls. Look at products from Mapei (AquaDefense) and Laticrete (Hydro Ban). Both offer up crack surpression and waterproofing. Much easier to work with than Kerdi.

I've bought Mapei AquaDefense for the shower walls but haven't installed it yet -- thanks!