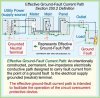

I am installing a "sub" circuit breaker panel in my garage. I recently discovered I have to install a second, isolated bus bar in the sub panel for the nuetral line seperate from the ground bar. ironicly the source for both bars can/will come from the same place. (the bus bar in the maine panel)

i spoke to a licensed electrician who addmitted it makes no sense to him either.

i spoke to a licensed electrician who addmitted it makes no sense to him either.