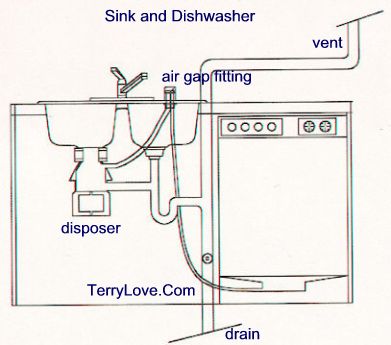

take the clean out off and repalce it with a AAV and it "would" work...even if that sink line is vented within the proper distance downstream you have an "S" trap in that picture and it will siphon itself dry without a source of air above it

but is the extra "engineering" worth while?...I don't think so....in fact, my opinion is that it creates more problems than it solves....a sched 40 male or female adapter on a brass tailpiece is pretty secure...can it leak?...certainly....no installation is bulletproof...but it will likely not

by using fernco's you are simply trading one mechanical connection for another....a fernco can leak also

also have what appear to be short sweep elbows in the horizontal.....if this guy is a master(whatever that is) plumber he should know that is wrong

you are going to have to use an AAV in this installation and that is the mother of all mechanical fittings that will fail at some point...not to mention the fact that they are inherently inferior to a good old fashioned "standard practice" vent that exhausts to the open air..

not to mention the fact that you are just making it even more difficult to clean the trap by using a glue type..

sometimes the "better" way isnt better just different and the tried and true methods stick around for a reason....problems usually are a result of poor workmanship, not the method..

sure, plumbing evolves like everything else and new ideas come around all the time that actually make an improvement over the old way

this just isnt one of them

and as Forrest Gump would say...."thats all I got to say about that"

Good Luck