dstutz

New Member

Ok, let me start this off by saying I'm pretty sure I need a new pressure tank but I'm curious about why it had almost no pressure, and here's my odyssey, feel free to skip to the end for my actual questions.

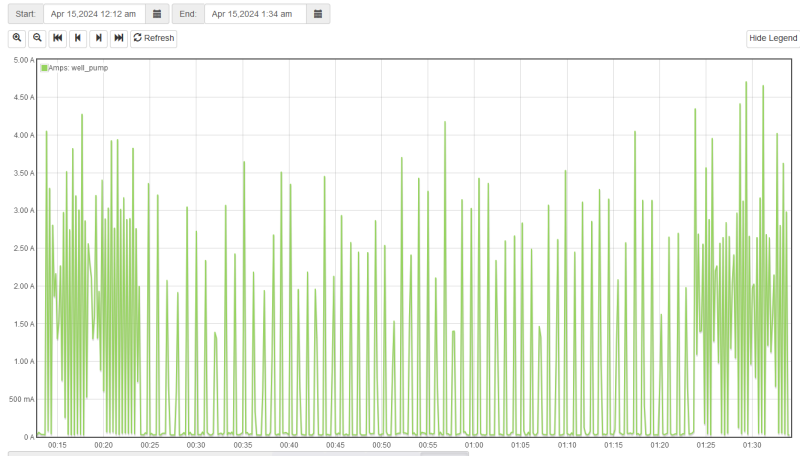

We've owned the house since Aug 2011. Of course I had no idea (or forgot after someone told me) that this was something that needed inspection/maintenance soooooo I've never even thought about the pressure tank in all this time. The last time we had a softener regeneration ~ 6 days ago, my wife was woken up by the clicking of the pressure switch which of course is just below our bedroom in the crawl. I have an electricity monitor and looked into it and noticed the pump was cycling a good bit (and I had no idea what proper cycling is). Here's of shot of that regen. When I zoomed in a little more I stopped counting over 30 for just the first 10 min backwash (2.4 gpm, followed by 60 min draw then another 10 min for rinse).

Still not really realizing how bad my problem is I ordered a new pressure gauge (old one wasn't reading properly anymore, it's showing 30-some psi not installed) and a pressure switch (though I stupidly got one with a LP cut-off before realizing why that was a bad idea, but I digress). Yesterday morning I we took a 13 minute shower and there were 33 cycles. Then I really started to understand a little better what was going on.

We found the paperwork on the well pump (1/2HP 7GPM Gould 7G505422 installed 10/8/99) and the pressure tank (Flotec FP7120 35 gallon, installed 4/13/11, also a new tank tee, check valve, gauge, drain, cut off valve and pressure switch at this install). According to the manual, that tank is supposed to give us 9.3 gallons of draw-down at 40-60 psi.

So I opened up a faucet and drained down the pressure until it stopped flowing then I checked the air valve on the tank and no water was coming out. I attached my bicycle pump and the needle barely moved.

Lot's of pumping and very sore arms later I got up to 38psi. I remember from doing work before the gauge was broken we had 40-60 pressure switch setup. I then did some testing and things were a lot better but still didn't seem like we were getting enough draw-down. I then recalled I had closed the faucet before pumping so I had created a closed system. Sooooo, I drained everything down again and since I had it drained down I decided to replace the gauge so I'd really know what was going on with the pressure. Then I left the faucet open....I put the bicycle pump back on and it was VERRRRY low again. I thought it was bad before, but it took so long to FINALLY get up to 38 psi. Now I had the proper air charge and a gauge that told the truth so I started doing some tests and noticed the pressure switch had more of a 33-62psi range so I started to try to adjust that and I just couldn't get the cut in to go higher without also raising the cut out and at one point I thought I was going to pop the 75PSI PRV in my face and ran up out of the crawlspace to flip the breaker off because, to add to my calamity, the on-off switch right there for the pump had failed on.

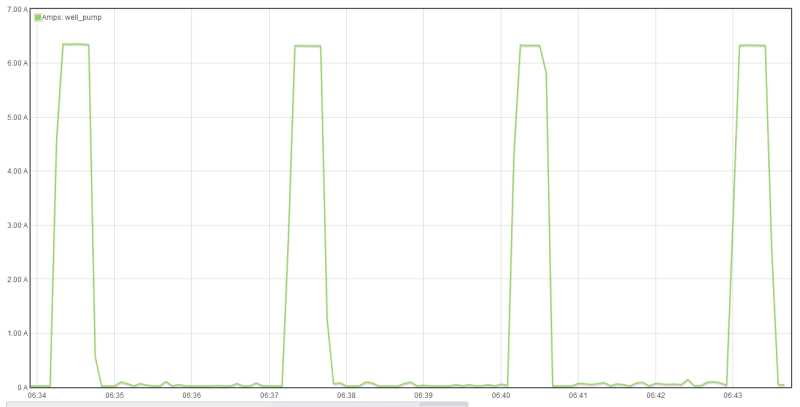

I drained everything down again put on the new switch and wired it up and we're happily running 40-60psi now. I also notice the proper behavior of the pressure rapidly dropping to 0 after falling before 40 vs slowly dropping and dropping and dropping (which, in a way is actually sort of nice when the power goes out to still be able to get SOME water). This is also when I replaced the pump on/off with a new DPST switch so I can cut the power right there at the tank.

I don't *think* the tank was waterlogged, I was knocking it along the side, and no water came out the valve. I *didn't* rock it when it was empty. I was able to get it pumped up to 38PSI. I'm still not 100% convinced everything is working properly but this morning's shower cause only 4 pump cycles. The pump doesn't seem to be running a full minute and I don't think we're getting the full draw-down we should (according to the softener the shower appears to be around 1.5gpm most of the time but it's a little higher at the top end but I know it doesn't stay there long). It looks like ~3 minutes between cycles and that's only 4.5gallons at 1.5GPM or 6 @ 2GPM. The pump should be running longer than a minute to get 9.3 gallons in there at 7GPM.

I checked back in time and my monitor only has "high resolution" data, ie showing quick spikes for the pump, for 1 year and it seems this has been slowly developing over the last 2-3 years as it was 14 cycles for a shower last May (vs 33 the other day) which is obviously still too many but less than half as bad.

All things considered, this is a huge improvement. I don't expect it to last so as I said I am expecting to need a new tank which I think I'm going to get a real plumber to do because I just don't see how I can get all those threaded connections together at once so close to the floor. After all this I have some actual questions:

1) Is it common/possible for the pre-charge to slowly leak out over time vs the bladder letting water in?

2) Any ideas why we don't seem to be getting 9 gallons of draw-down still?

3) I Used Amtrol's tank sizing calculator and they recommend the 202XL which is 26g which yields a 7gal draw-down (which I think is the proper sizing for getting a 1 minute run time on the pump). That tank is 39" high and our crawl has about 48" to the bottom of the floor joists and it's sitting on a couple pieces of wood to raise the plumbing up off the floor a little (the drain valve is at an angle and it's still pretty hard to hook a hose up to it). The next size up is 32g which is 42" high and the next one up is a 44g what is more squat and only 36" tall, it's actually very similar size to our current 35g Flotec. How bad would it be to bump up to the 44g tank just to have better physical size or do I just forget about any of this and let it be a plumber's problem?

4) Pump still seems to be fine but I'm curious how much life I took off it as it's already approaching 25 years old.

I don't really care that much about hanging around the lower pressure longer, which I know a bigger tank would do, because apparently we've been hanging out closer to 33 PSI lately and that was still working but noticeable now that I'm comparing it to a proper 40-60 setup.

Oh...and valveman, feel free to jump in here with CSV, but I'm aware of your product and have looked into it already. 1 reason sort of holding me back is we lose power often enough that I'd hate to only have *at most* 1 gallon of water sitting in the tank for an outage.

We've owned the house since Aug 2011. Of course I had no idea (or forgot after someone told me) that this was something that needed inspection/maintenance soooooo I've never even thought about the pressure tank in all this time. The last time we had a softener regeneration ~ 6 days ago, my wife was woken up by the clicking of the pressure switch which of course is just below our bedroom in the crawl. I have an electricity monitor and looked into it and noticed the pump was cycling a good bit (and I had no idea what proper cycling is). Here's of shot of that regen. When I zoomed in a little more I stopped counting over 30 for just the first 10 min backwash (2.4 gpm, followed by 60 min draw then another 10 min for rinse).

Still not really realizing how bad my problem is I ordered a new pressure gauge (old one wasn't reading properly anymore, it's showing 30-some psi not installed) and a pressure switch (though I stupidly got one with a LP cut-off before realizing why that was a bad idea, but I digress). Yesterday morning I we took a 13 minute shower and there were 33 cycles. Then I really started to understand a little better what was going on.

We found the paperwork on the well pump (1/2HP 7GPM Gould 7G505422 installed 10/8/99) and the pressure tank (Flotec FP7120 35 gallon, installed 4/13/11, also a new tank tee, check valve, gauge, drain, cut off valve and pressure switch at this install). According to the manual, that tank is supposed to give us 9.3 gallons of draw-down at 40-60 psi.

So I opened up a faucet and drained down the pressure until it stopped flowing then I checked the air valve on the tank and no water was coming out. I attached my bicycle pump and the needle barely moved.

Lot's of pumping and very sore arms later I got up to 38psi. I remember from doing work before the gauge was broken we had 40-60 pressure switch setup. I then did some testing and things were a lot better but still didn't seem like we were getting enough draw-down. I then recalled I had closed the faucet before pumping so I had created a closed system. Sooooo, I drained everything down again and since I had it drained down I decided to replace the gauge so I'd really know what was going on with the pressure. Then I left the faucet open....I put the bicycle pump back on and it was VERRRRY low again. I thought it was bad before, but it took so long to FINALLY get up to 38 psi. Now I had the proper air charge and a gauge that told the truth so I started doing some tests and noticed the pressure switch had more of a 33-62psi range so I started to try to adjust that and I just couldn't get the cut in to go higher without also raising the cut out and at one point I thought I was going to pop the 75PSI PRV in my face and ran up out of the crawlspace to flip the breaker off because, to add to my calamity, the on-off switch right there for the pump had failed on.

I drained everything down again put on the new switch and wired it up and we're happily running 40-60psi now. I also notice the proper behavior of the pressure rapidly dropping to 0 after falling before 40 vs slowly dropping and dropping and dropping (which, in a way is actually sort of nice when the power goes out to still be able to get SOME water). This is also when I replaced the pump on/off with a new DPST switch so I can cut the power right there at the tank.

I don't *think* the tank was waterlogged, I was knocking it along the side, and no water came out the valve. I *didn't* rock it when it was empty. I was able to get it pumped up to 38PSI. I'm still not 100% convinced everything is working properly but this morning's shower cause only 4 pump cycles. The pump doesn't seem to be running a full minute and I don't think we're getting the full draw-down we should (according to the softener the shower appears to be around 1.5gpm most of the time but it's a little higher at the top end but I know it doesn't stay there long). It looks like ~3 minutes between cycles and that's only 4.5gallons at 1.5GPM or 6 @ 2GPM. The pump should be running longer than a minute to get 9.3 gallons in there at 7GPM.

I checked back in time and my monitor only has "high resolution" data, ie showing quick spikes for the pump, for 1 year and it seems this has been slowly developing over the last 2-3 years as it was 14 cycles for a shower last May (vs 33 the other day) which is obviously still too many but less than half as bad.

All things considered, this is a huge improvement. I don't expect it to last so as I said I am expecting to need a new tank which I think I'm going to get a real plumber to do because I just don't see how I can get all those threaded connections together at once so close to the floor. After all this I have some actual questions:

1) Is it common/possible for the pre-charge to slowly leak out over time vs the bladder letting water in?

2) Any ideas why we don't seem to be getting 9 gallons of draw-down still?

3) I Used Amtrol's tank sizing calculator and they recommend the 202XL which is 26g which yields a 7gal draw-down (which I think is the proper sizing for getting a 1 minute run time on the pump). That tank is 39" high and our crawl has about 48" to the bottom of the floor joists and it's sitting on a couple pieces of wood to raise the plumbing up off the floor a little (the drain valve is at an angle and it's still pretty hard to hook a hose up to it). The next size up is 32g which is 42" high and the next one up is a 44g what is more squat and only 36" tall, it's actually very similar size to our current 35g Flotec. How bad would it be to bump up to the 44g tank just to have better physical size or do I just forget about any of this and let it be a plumber's problem?

4) Pump still seems to be fine but I'm curious how much life I took off it as it's already approaching 25 years old.

I don't really care that much about hanging around the lower pressure longer, which I know a bigger tank would do, because apparently we've been hanging out closer to 33 PSI lately and that was still working but noticeable now that I'm comparing it to a proper 40-60 setup.

Oh...and valveman, feel free to jump in here with CSV, but I'm aware of your product and have looked into it already. 1 reason sort of holding me back is we lose power often enough that I'd hate to only have *at most* 1 gallon of water sitting in the tank for an outage.