Benjdow

New Member

Hello,

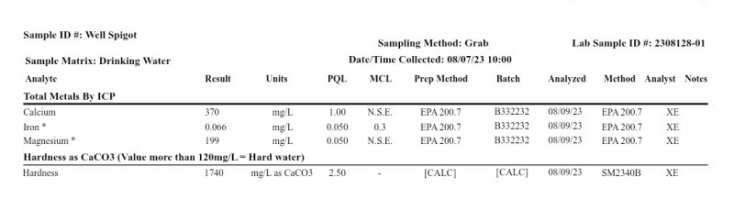

I'm hoping I can get some help from you smart folks on a water softener rehab project.

We're on well water and I finally got the water tested, it's about 40gpg higher than I thought. Our water hardness is 101gpg. Our water softener has been installed for 20 years, and we've been in the house for 7 years. I changed the valve, but haven't done anything else. I've bypassed it since resin is coming through plumbing.

I'm open to any recommendations (even if it's drastic change from what we have now) and could really use the help.

This is what I currently have:

3.0 ^ft resin tank (tank & resin 20 years old)

Fleck 5600sxt (4 years old)

.50 gpm 1.5lb salt/min

Injector 1

Drain flow 2.0 gpm

I'm hoping I can get some help from you smart folks on a water softener rehab project.

We're on well water and I finally got the water tested, it's about 40gpg higher than I thought. Our water hardness is 101gpg. Our water softener has been installed for 20 years, and we've been in the house for 7 years. I changed the valve, but haven't done anything else. I've bypassed it since resin is coming through plumbing.

I'm open to any recommendations (even if it's drastic change from what we have now) and could really use the help.

This is what I currently have:

3.0 ^ft resin tank (tank & resin 20 years old)

Fleck 5600sxt (4 years old)

.50 gpm 1.5lb salt/min

Injector 1

Drain flow 2.0 gpm