Jeremy Harris

Member

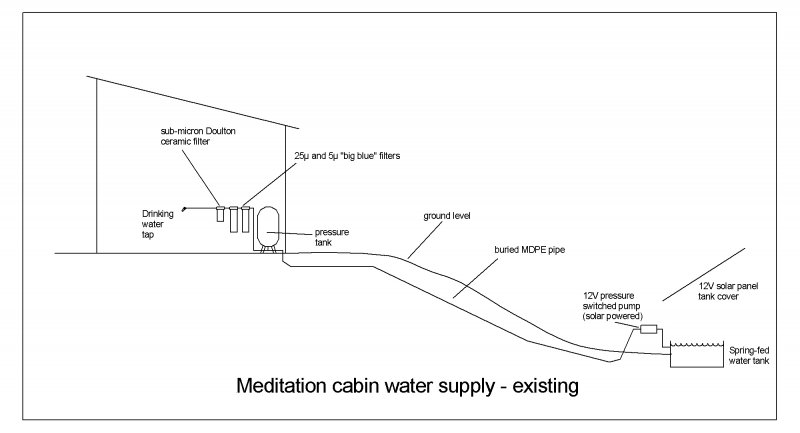

An acquaintance has heard about my borehole supply trials and tribulations and came over this afternoon to ask my advice about a drinking water supply she has in her "meditation cabin". Basically this is a tiny wooden shed deep in some woodland, where she goes to meditate. She has to hike in, as there's no nearby road or track, so everything that goes in there has to be hand carried. Some years ago someone set up a drinking water supply for her, to save her having to carry water in (this lady is probably around 70 years old, at a guess). The diagram below is pretty much what she described to me today, and she has some problems with it she'd like to try and fix:

The system works using a solar panel driving a small 12V pressure set pump, with a pressure switch, that's located down in the valley below the cabin. This draws water from a small terracotta cistern that catches water from a tiny spring, little more than a trickle. The solar panel acts as a cover over the cistern, together with some stone walls around it. Whenever there's enough sun the pump runs and pressurises the bladder tank in the cabin, then shuts off when it's up to pressure. The cabin can be empty for weeks, and then used for a few days, and she says there is always enough water (it's only a drinking water supply, I think). To make the water safe to drink it passes through a couple of big blue pre-filters, then a Doulton ceramic filter to take out the bugs.

The problem is that the pre-filters clog randomly, they can last for six months, but sometimes she goes up there and they've clogged after a week. Carrying spare filters in is a nuisance, she tells me, and she asked if I could come up with a system that did away with the need to change filters.

I'm afraid I don't know the specs of any of the existing kit, but do know that the buried feed pipe is about the size of the ladies little finger, so my guess is that it's 1/2" at the biggest, probably either 10mm or 12mm MDPE, so the 12V pump is most likely a very low capacity one, maybe one like those used on small boats. She's never had a problem with the pump or the solar panel system, both of which have worked well for years. She does clean out the cistern from time to time, but I suspect that it sometimes picks up extra sediment if it's been raining, and that may well be what sometimes clogs the pre-filters quickly.

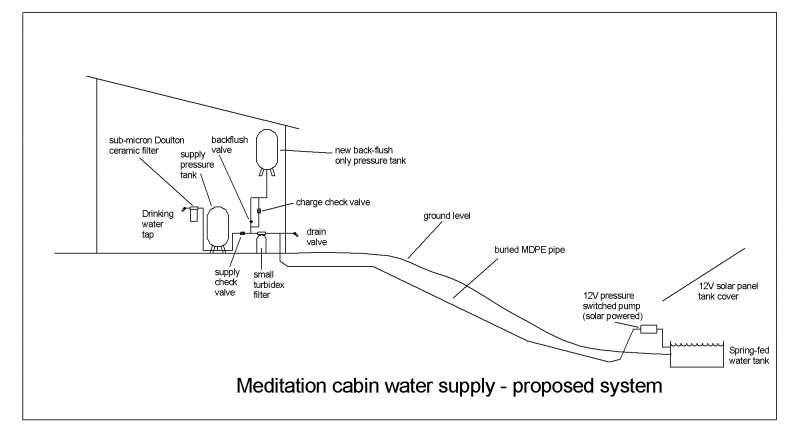

As it happens I have an unused 100 litre (~26 gallon) pressure tank, and I showed this to her today and she thinks she has room for it, If I can put it high up where her sleeping platform is in the roof space. So, what I was thinking of doing was getting a small filter tank, something like a 6" x 35", with a standard head, riser and screen, put in a gravel bed and 2/3rds fill it with turbidex. I'd then use the second pressure tank purely for filter manual backwash, like this:

The idea is that when the sun shines both pressure tanks get charged with filtered water, with the check valves isolating them from each other. Her drinking water supply pressure tank will always be full of pre-filtered water, so the Doulton filter should work as it does at the moment. She reckons that tank holds more than enough water for the length of time she stays there, so that bit should work fine, I think. Before she leaves the cabin, she needs to open the drain valve outside and open the backflush valve, which will discharge a few gallons at a fairly high pressure through the turbidex filter to clean it. She can then close both the backflush valve and the outside drain valve and go away and let the system recharge, ready for her next visit.

Apart from the fact that I'll probably have to be the one who lugs all this kit through the woods and install it, it seems to me to be a workable solution. The main advantage is that she won't need to keep buying big blue pre-filters, so the cost of a small filter tank, some turbidex and a few fittings should soon be recovered.

Can anyone see any major problems with this idea, please?

The system works using a solar panel driving a small 12V pressure set pump, with a pressure switch, that's located down in the valley below the cabin. This draws water from a small terracotta cistern that catches water from a tiny spring, little more than a trickle. The solar panel acts as a cover over the cistern, together with some stone walls around it. Whenever there's enough sun the pump runs and pressurises the bladder tank in the cabin, then shuts off when it's up to pressure. The cabin can be empty for weeks, and then used for a few days, and she says there is always enough water (it's only a drinking water supply, I think). To make the water safe to drink it passes through a couple of big blue pre-filters, then a Doulton ceramic filter to take out the bugs.

The problem is that the pre-filters clog randomly, they can last for six months, but sometimes she goes up there and they've clogged after a week. Carrying spare filters in is a nuisance, she tells me, and she asked if I could come up with a system that did away with the need to change filters.

I'm afraid I don't know the specs of any of the existing kit, but do know that the buried feed pipe is about the size of the ladies little finger, so my guess is that it's 1/2" at the biggest, probably either 10mm or 12mm MDPE, so the 12V pump is most likely a very low capacity one, maybe one like those used on small boats. She's never had a problem with the pump or the solar panel system, both of which have worked well for years. She does clean out the cistern from time to time, but I suspect that it sometimes picks up extra sediment if it's been raining, and that may well be what sometimes clogs the pre-filters quickly.

As it happens I have an unused 100 litre (~26 gallon) pressure tank, and I showed this to her today and she thinks she has room for it, If I can put it high up where her sleeping platform is in the roof space. So, what I was thinking of doing was getting a small filter tank, something like a 6" x 35", with a standard head, riser and screen, put in a gravel bed and 2/3rds fill it with turbidex. I'd then use the second pressure tank purely for filter manual backwash, like this:

The idea is that when the sun shines both pressure tanks get charged with filtered water, with the check valves isolating them from each other. Her drinking water supply pressure tank will always be full of pre-filtered water, so the Doulton filter should work as it does at the moment. She reckons that tank holds more than enough water for the length of time she stays there, so that bit should work fine, I think. Before she leaves the cabin, she needs to open the drain valve outside and open the backflush valve, which will discharge a few gallons at a fairly high pressure through the turbidex filter to clean it. She can then close both the backflush valve and the outside drain valve and go away and let the system recharge, ready for her next visit.

Apart from the fact that I'll probably have to be the one who lugs all this kit through the woods and install it, it seems to me to be a workable solution. The main advantage is that she won't need to keep buying big blue pre-filters, so the cost of a small filter tank, some turbidex and a few fittings should soon be recovered.

Can anyone see any major problems with this idea, please?