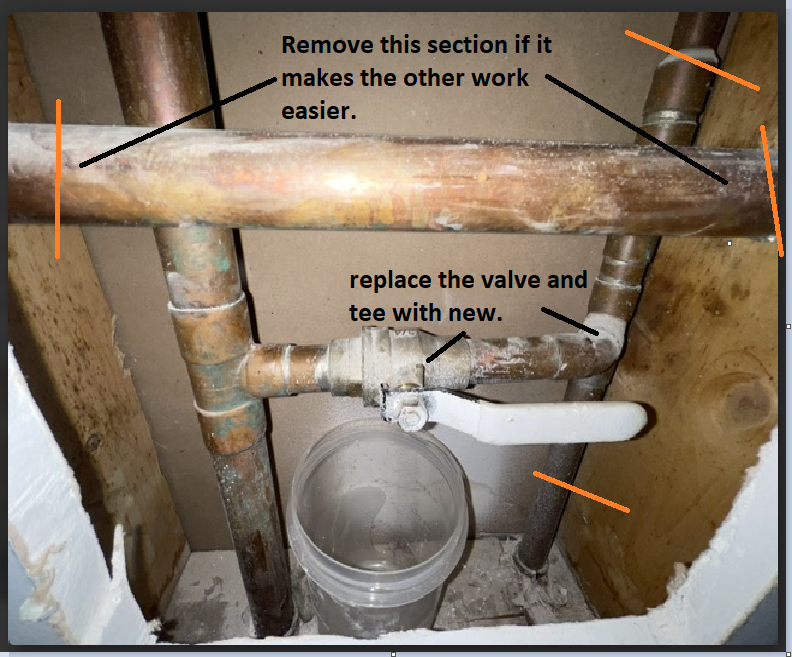

This was installed about a year ago. Developed minor leak here recently on left side of the valve where soldered. Thinking I’ll cut section just right of the valve, unsweat the valve, then use stopless coupling to reconnect. Kind of worried about how to get everything to fit though given the tight spacing.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best way to fix minor leak in tight spot?

- Thread starter PepeLePue

- Start date

Users who are viewing this thread

Total: 3 (members: 0, guests: 3)

Tuttles Revenge

In the Trades

- Messages

- 4,205

- Reaction score

- 1,460

- Points

- 113

If I were to plan this repair: I would likely cut out the valve and tee to the right with the couplings and reducer. Then replace it all with new. If the other pipe that is horizontal is in the way, remove and replace it too to make the work easier.

Sponsor

Paid Advertisement

incredibly detailed reply. Thank you!If I were to plan this repair: I would likely cut out the valve and tee to the right with the couplings and reducer. Then replace it all with new. If the other pipe that is horizontal is in the way, remove and replace it too to make the work easier.

View attachment 97244

Pipes above don't really interfere thankfully (at least doesn't appear that way).

I was hoping not to touch the vertical pipe on the right side, does that need to come out in order to get the valve back in and everything fitted together? Or can I do it by unsweating the street 90 out of the tee?

Thanks again!

Jeff H Young

In the Trades

or just cut the short piece next to the ball valve drain water down heat left side flux and ja,m solder in get good cap on there install repair coupling and burn that . if its an easy one and you are lucky.

Or if you arent feeling quits so lucky proceed this way . Cut pipe on right side of ball valve unsweat street 45 toss it unsweat ball valve leaving the little stub thats there. clean it all and rebuild with new ball valve and a little bit of pipe and a steet 45 ( I dont think youll need a repair coupling this way) but youll need to wire brush heat and clean the socket very well on the tee. Good Luck it can be easy or hard depending mostly on if water keeps coming you are screwed !

Or if you arent feeling quits so lucky proceed this way . Cut pipe on right side of ball valve unsweat street 45 toss it unsweat ball valve leaving the little stub thats there. clean it all and rebuild with new ball valve and a little bit of pipe and a steet 45 ( I dont think youll need a repair coupling this way) but youll need to wire brush heat and clean the socket very well on the tee. Good Luck it can be easy or hard depending mostly on if water keeps coming you are screwed !

Can you clarify on the first part? What do you mean? Cut it to get water out and then heat it and put a repair coupling right over the existing piece? The repair couplings look like they come in 6" length. Is that intended to be cut to size that you need basically? Vs. a standard slip coupling which is specific length?or just cut the short piece next to the ball valve drain water down heat left side flux and ja,m solder in get good cap on there install repair coupling and burn that . if its an easy one and you are lucky.

Or if you arent feeling quits so lucky proceed this way . Cut pipe on right side of ball valve unsweat street 45 toss it unsweat ball valve leaving the little stub thats there. clean it all and rebuild with new ball valve and a little bit of pipe and a steet 45 ( I dont think youll need a repair coupling this way) but youll need to wire brush heat and clean the socket very well on the tee. Good Luck it can be easy or hard depending mostly on if water keeps coming you are screwed !

Fitter30

Well-Known Member

Three piece sweat ball valve. Can be taken apart to solder and inspected.

www.menards.com

www.menards.com

NIBCO® 3/4" Sweat 3-Piece Lead-Free Bronze Full Port Ball Valve

The NIBCO® three-piece lead-free* ball valve is constructed of lead-free dezincification-resistant (DZR) high quality performance bronze silicon alloy per ASTM specifications. The valve features solder ends for easy installation. The valve is recommended for applications that deliver water for...

Tuttles Revenge

In the Trades

- Messages

- 4,205

- Reaction score

- 1,460

- Points

- 113

From years of experience I know that I could do the least amount of work to repair that one leak. But I also know that its much easier and faster sometimes to remove a larger section of pipe which allows me to work quicker with less chances of having to redo the work.

Un soldering a fitting is much more difficult than soldering a new fitting.

**On Unsoldering that street 45**

It really depends on how much wiggle room you have in that horizontal section from the valve. If each of those vertical sections are held in tightly the chances of getting that 45 out of the tee are pretty slim. If it were a 90 you would be able to pull it straight away from the tee. But because its a 45, as the fitting moves out from the wall, it needs to move also to the left. But its being held in place by the vertical on the left. That's the reason I think it may be easier to cut the vertical section on the right side of the valve so that you can unsolder the valve and it will slide off to the right un-encumbered by the vertical on the right.

***All things I can only guess from a photo of a small section of the work***

Un soldering a fitting is much more difficult than soldering a new fitting.

**On Unsoldering that street 45**

It really depends on how much wiggle room you have in that horizontal section from the valve. If each of those vertical sections are held in tightly the chances of getting that 45 out of the tee are pretty slim. If it were a 90 you would be able to pull it straight away from the tee. But because its a 45, as the fitting moves out from the wall, it needs to move also to the left. But its being held in place by the vertical on the left. That's the reason I think it may be easier to cut the vertical section on the right side of the valve so that you can unsolder the valve and it will slide off to the right un-encumbered by the vertical on the right.

***All things I can only guess from a photo of a small section of the work***

Last edited:

Your analysis is correct. I was thinking I would cut the section of pipe just right of the valve first, so that I can freely wiggle out that street 90 (to your point, needing to move towards the camera and left of the picture) i could first turn the pipe counter clockwise and then pull it out. Maybe I'm being over confident. Your idea could work though as I agree its been dificult to re-use fittings for me because they get hard to insert/remove/etc. Much easier to just use a new one (and I have plenty of fittings thankfully).

Jeff H Young

In the Trades

Totally agree I often just wack it out with a saws all clean it up and rebuild, Weve all resoldered leaking joints withy sucess and failure We get a feeling and see options sometimes give it a try.From years of experience I know that I could do the least amount of work to repair that one leak. But I also know that its much easier and faster sometimes to remove a larger section of pipe which allows me to work quicker with less chances of having to redo the work.

Un soldering a fitting is much more difficult than soldering a new fitting.

**On Unsoldering that street 45**

It really depends on how much wiggle room you have in that horizontal section from the valve. If each of those vertical sections are held in tightly the chances of getting that 45 out of the tee are pretty slim. If it were a 90 you would be able to pull it straight away from the tee. But because its a 45, as the fitting moves out from the wall, it needs to move also to the left. But its being held in place by the vertical on the left. That's the reason I think it may be easier to cut the vertical section on the right side of the valve so that you can unsolder the valve and it will slide off to the right un-encumbered by the vertical on the right.

***All things I can only guess from a photo of a small section of the work***

Only a 1 year old valve I dont know I might give it a try but sure dont question cutting it out and throwing it away Might take me twice as long or have it done in 20 minutes and save 40 bucks in parts

I've got an inspection coming up soon. I don't think they're going to look at this shut off (just a shut off for a bathroom). I think I'll wait for that to be over and then try my luck in case I get into a bind. Don't want to fail the inspection because there is no water to the bathrooms!

Similar threads

- Replies

- 5

- Views

- 312

- Replies

- 14

- Views

- 611

- Replies

- 18

- Views

- 1K

- Replies

- 22

- Views

- 2K

- Replies

- 4

- Views

- 2K