Sluggo

Member

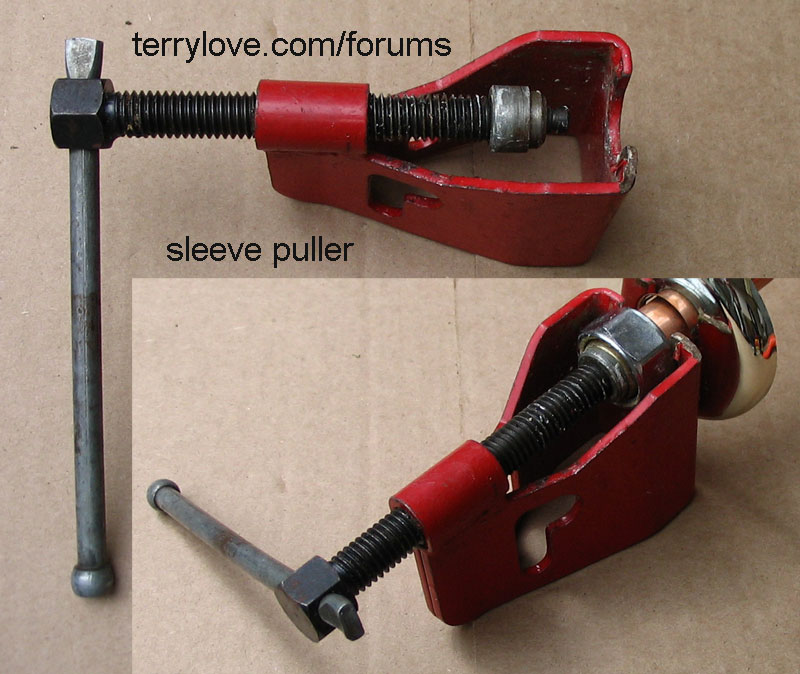

I'm a pretty experienced DIY plumber. Six months ago I installed 1/2" copper piping for a new powder room, with a pair of standard shutoff valves under the sink. After a couple of weeks I noticed a very slow leak from the compression fitting nut on one of the valves, so I cranked it down another quarter turn with a pair of wrenches and that seemed to stop it. It's been fine for months, but last week I just happened to look under the sink and found the same valve leaking again, but even more slightly (only about one drop an hour). However, I had to really crank down to stop the leak originally and am not sure I want to try to tighten it any more (and possibly distort the copper tubing). So, I'm thinking of removing the valve, using a compression ring puller to get the old ring off, and then installing a new valve. However, the working space is really tight because the leaking valve is about an inch away from the side of the cabinet under the sink, so I want to do the easiest thing that fixes this for once and for all.

I see three options:

1) Leave the old valve in place and try to tighten the nut some more (can you screw up the copper tubing by over tightening or make it impossible to get the old ring off?)

2) Take the old valve off, leave the existing compression ring in place, and just install the new valve

3) Do a complete install of a new valve as described above

I'd like to hear opinions on how you would approach this. Thanks.

I see three options:

1) Leave the old valve in place and try to tighten the nut some more (can you screw up the copper tubing by over tightening or make it impossible to get the old ring off?)

2) Take the old valve off, leave the existing compression ring in place, and just install the new valve

3) Do a complete install of a new valve as described above

I'd like to hear opinions on how you would approach this. Thanks.

Last edited by a moderator: