powerlifter405

New Member

Howdy everyone

First time caller, 8 month lurker.

I'm installing a Mansfield alcove tub, acrylic whirlpool tub encased in fiberglass.

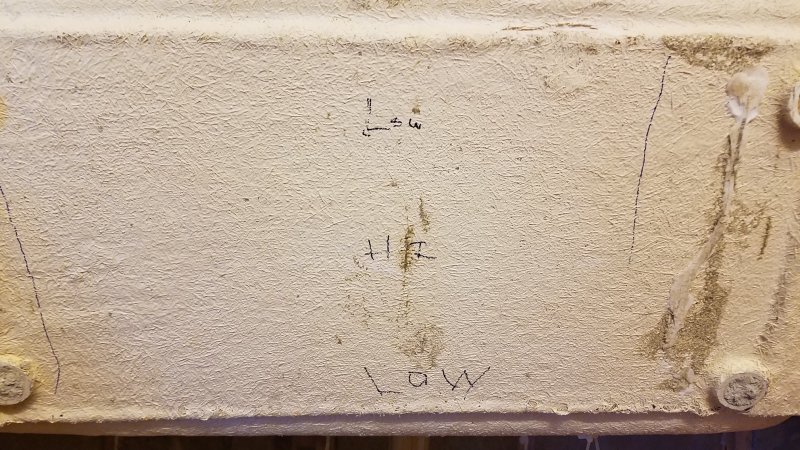

I have laid 3 mortar beds and I get a "spot" in the middle of the tub that has give. Each time I lay enough to compact, I set the tub in place and allow it to dry, I always wait 2 days for full cure. It get what feels like a soft spot in the exact same place every time. I took a pic of the inside of the tub, I initially outlined the area that gives when I walk/push on it so I could add extra mortar the other two times. Each time the same issue. I get mortar down, verify level and wait.

Today I pulled the tub and placed a level on the underside and lo-and-behold, the osb that is fiberglassed to the acrylic is cupped outward. The gap on the outsides are visible when I hold a level in the center of the osb. W/ the osb having a cup, the plastic will always have a little give on the tub side.

I got the tub last summer but the tear out and several other projects, family emergencies and now the gov shut down has put me behind. Thus i'm beyond the warranty period.

Any ideas on how I can fix this or if it will be ok?

Thanks

First time caller, 8 month lurker.

I'm installing a Mansfield alcove tub, acrylic whirlpool tub encased in fiberglass.

I have laid 3 mortar beds and I get a "spot" in the middle of the tub that has give. Each time I lay enough to compact, I set the tub in place and allow it to dry, I always wait 2 days for full cure. It get what feels like a soft spot in the exact same place every time. I took a pic of the inside of the tub, I initially outlined the area that gives when I walk/push on it so I could add extra mortar the other two times. Each time the same issue. I get mortar down, verify level and wait.

Today I pulled the tub and placed a level on the underside and lo-and-behold, the osb that is fiberglassed to the acrylic is cupped outward. The gap on the outsides are visible when I hold a level in the center of the osb. W/ the osb having a cup, the plastic will always have a little give on the tub side.

I got the tub last summer but the tear out and several other projects, family emergencies and now the gov shut down has put me behind. Thus i'm beyond the warranty period.

Any ideas on how I can fix this or if it will be ok?

Thanks