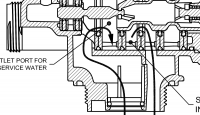

I need to change the resin in my softner. How is the clack control valve supposed to be removed? I know that I need to disconnect it from the bypass valve first.

Does the entire control valve spin off or is that a nut holding it on? If that is a nut that needs loosened, I can't get it to budge. Is there a special wrench that I need?

Thanks

Does the entire control valve spin off or is that a nut holding it on? If that is a nut that needs loosened, I can't get it to budge. Is there a special wrench that I need?

Thanks